Our partner, COMNET, conducted an interview with Matsukan, a century-old kendo equipment company that has adopted the GCC LaserPro Mercury III laser engraver. In the interview, they shared the reasons for choosing our laser machines, how they apply them, and the benefits they have experienced since implementation.

Company Name: Matsukan Industry Co., Ltd.

Major Business Items: Embroidery processing, patch production

Location: Saitama Prefecture, Japan

Facebook

GCC Products: GCC LaserPro Mercury III 25W Laser Engraver

What issues did you have before introducing the laser machine?

Our company was founded in 1907, starting with the production of kendo equipment, bayonet fencing protective gear, and judo uniforms. In 1945, we expanded into manufacturing hard baseballs, which became widely known nationwide under the brand namePine Ball. Even as we celebrated our 100th anniversary, we continue to carry on this tradition of craftsmanship, producing kendo gear, judo uniforms, and hard baseballs.

The idea of introducing a laser engraving machine arose from the desire to bring the production oftare name tagsin-house. These tags, attached to the “tare” (waist protector) of kendo armor, display the owner’s name and organization sewn onto indigo-dyed fabric. Until then, the fabric cutting process had been outsourced. We realized that handling this step internally with a laser machine would reduce costs and shorten lead times, which led us to seriously consider adoption.

At the same time, we also saw new opportunities—laser processing could be used to create commemorative goods and novelty items.

Much of our kendo gear, bayonet fencing gear, and judo uniforms are supplied to schools and police organizations. In particular, school clubs often look for commemorative items and novelties at graduation. We believed that by being able to offer such items alongside our core products, we could diversify our business and better serve our customers’ needs.

Installed Model: GCC LaserPro Mercury III Laser Engraver

Why introduce the GCC LaserPro laser machine?

In 2004, we introduced our first laser engraving machine, the Mercury (12W). At that time, our company president consulted an acquaintance who had been assisting us with embroidery machines, and through that connection, we were introduced to the GCC LaserPro laser engraver from COMNET.

After using it for more than ten years, the laser power had naturally decreased, so in 2019 we upgraded to the successor model, the Mercury III (25W).

When replacing their equipment, some companies opt for larger laser machines. However,we intentionally chose the Mercury’s successor. One of the biggest reasons is that the Mercury III ’ s working area (635 × 458 mm) perfectly matches the standard size of the fabric we use for name tags (600 × 450 mm).

Another key factor was the continued support of our sales representative, Mr. Goto, who has a background in kendo. His understanding of our products and needs makes it easy for us to consult with him with confidence.

These name tags, attached to kendo armor, display the wearer’s name and organization. With the laser engraving machine, the fabric for sewing the tags can now be precisely cut in-house.

Benefits of the GCC LaserPro

As planned, the introduction of the laser engraving machine allowed us to bring the production oftare name tagsin-house.

But the benefits did not stop there. We soon expanded its use to engraving names on wooden and bamboo swords, as well as producing brand labels —adding significant value to our products. In particular, the brand labels have been a major advantage, as they make theMatsukanbrand instantly recognizable and help us stand out from our competitors.

Although wooden and bamboo swords are larger than the Mercury III ’s standard working area, by opening the front and rear doors we are still able to process them effectively. While it requires some care to manage the smoke produced during engraving, our exhaust system handles it without any issues.

HIRAMEKI Series Kote – Instantly recognizable Matsukan brand adds a unique edge, clearly differentiating

Works by Matsukan’s laser engraving

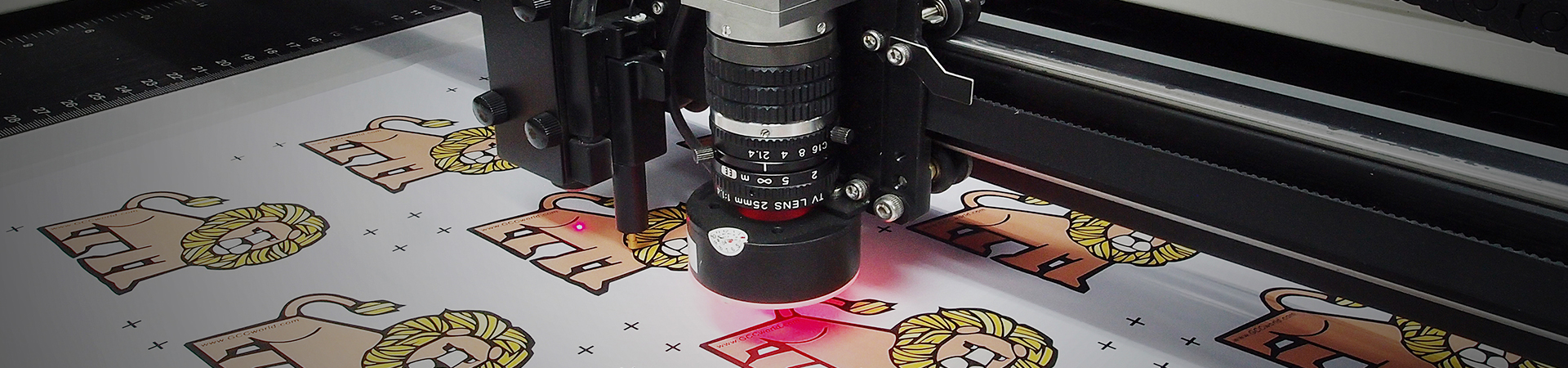

The laser engraving machine is mainly used for engraving names on kendo equipment, wooden swords, and bamboo swords. It also plays a key role in producing original logo patches that are attached to the company’s own brand of protective gear.

In addition, commemorative items such as engraved wooden memorial clocks and photo frames have become popular, offering customers unique keepsakes with a personal touch.

Name engraving on wooden and bamboo swords; even oversized bamboo swords can be processed by opening the laser engraver’s front and rear doors.

Wooden memorial clocks and photo frames have helped diversify our business, serving as popular commemorative items and novelty gifts.

What are your prospects for the laser business?

We see great potential for expansion beyond martial arts equipment, into related goods and commemorative items. The possibilities continue to grow, and we are excited about exploring new opportunities. Going forward, we hope to keep close communication with COMNET and continue learning, so that we can turn new ideas into reality.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤Discover the Power of Laser Engraving

➤Glass Laser Engraving Guide: Tips and Tricks

➤Making Money with a Laser Engraver: 6 Profitable Product Ideas