Industries That Benefit from Laser Equipment: Key Features, Types & Applications | GCC: Laser Machines Leader Since 1989

Wondering which industries gain the most from laser equipment?From metal fabrication and electronics manufacturing to art and design, the precision and throughput of laser equipment are reshaping production. Different systems—CO₂, fiber, and diode laser equipment—are designed for specific materials and processes. Choosing the right machine ensures you get the best results for your applications.

What Is Laser Equipment? From Invention to Industry Standard

The story of laser equipment began in 1960 with the invention of the first ruby laser, originally applied in scientific and military research. Over time, improvements in power control, wavelength options, and processing accuracy made laser systems smaller, more user-friendly, and increasingly affordable. These advances paved the way for their adoption across industries.

Today, laser equipment is indispensable. From metal cutting and electronics micro-processing to medical applications and artistic creation, lasers deliver results that traditional tools can’t match. Its rapid adoption comes from three advantages: high precision, low material loss, and seamless integration with automation—driving higher efficiency and better cost management.

Types of Laser Equipment and Their Ideal Applications

Laser equipment can be classified not only by the light source but also by factors like processing precision, material compatibility, and return on investment (ROI). Knowing these differences is essential for choosing the right system.

Laser Equipment by Light Source

| Laser Type | Key Features & Materials | Advantages | Best Use Cases |

| CO₂ Laser | Wavelength 9.3~10.6 μm; ideal for wood, acrylic, leather, textiles | Smooth edges, high aesthetic finish, versatile | Product engraving, non-metal cutting |

| Fiber Laser | Wavelength ~1,060 nm; high energy density for metals | High strength, low consumables, great for continuous runs | Metal part marking, thin metal cutting, industrial coding |

| Diode Laser | Compact design, simple structure | Affordable, beginner-friendly | Hobby projects, educational training |

Common Laser Types by Processing Method

| Processing Method | How It Works | Advantages | Best Use Cases |

| Gantry/Flatbed | Laser head moves on X-Y axis over the material | Handles large areas, thicker materials | Large-format cutting, deep engraving |

| Galvo/Scanner | Stationary head with high-speed mirrors to direct the beam | Ultra-fast, high repeatability | Metal coding, serial number marking, fine detail engraving |

Common Applications: Where Laser Equipment Delivers Value

Laser equipment extends far beyond the factory floor. With its precision, stability, and repeatability, it enhances product quality, speeds up workflows, and ensures reliable traceability across industries.

✔️Manufacturing

Laser cutting, welding, and marking for both metals and non-metals. Achieve accurate dimensions, smooth edges, and consistent batch quality—perfect for machining parts and enclosures.

✔️Art & Design

Custom engraving, model making, and jewelry detailing. Lasers reproduce intricate textures and 3D forms quickly while preserving fine aesthetics, making them indispensable for creative industries.

✔️Electronics

High-resolution PCB marking and micro-processing on tiny surfaces without affecting performance. Supports high-density circuit layouts and enhances product traceability.

✔️Automotive & Aerospace

Durable marking and component manufacturing for heat- and corrosion-resistant parts that meet strict safety and compliance requirements.

How to Choose Laser Equipment: 5 Key Buying Criteria

Buying laser equipment isn’t just about price or appearance. Start by considering your materials, tolerances, and production goals. Here are five essential factors to guide your decision:

Power Output & Wavelength Compatibility

Match materials to the right combination. CO₂ laser equipment excels on non-metals, while fiber laser equipment is best for metal marking/cutting.

Work Area & Machine Footprint

Make sure the working envelope fits your largest part and confirm that your facility has enough space. Proper planning avoids installation issues and simplifies material handling.

Software Integration & Ease of Use

Choose a system that works seamlessly with Adobe Illustrator, CorelDRAW, and AutoCAD. An intuitive user interface reduces training time and helps maximize productivity.

Cooling System & Maintenance

Stable cooling prevents overheating and preserves cut quality while extending component life. A few models (MG380 Hybrid, E200S, E200SL) use CO₂ glass tubes and require a water chiller for optimal stability.

Safety Features & Certifications

Prioritize machines with protective housings, emergency stops, and interlocks. Always check for compliance with international safety standards to safeguard operators and ensure legal use.

Top Laser Equipment Picks for Performance & Stability

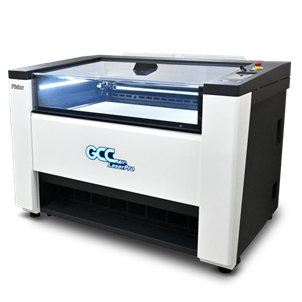

Laser Engraver | Piolas 400 Series

The GCC LaserPro Piolas 400 Series blends speed and reliability—up to 175 ips (4.44 m/s)—to reduce cycle time and boost productivity. SmartEYES™ and real-time CCD alignment make setup intuitive and cut rework. From fine engraving to fast cutting, output stays consistent for high-volume, high-quality demands.

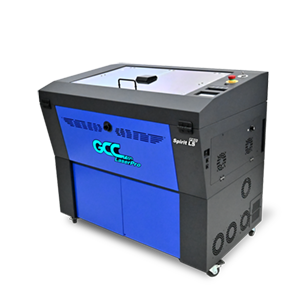

Laser Engraver | Spirit LS PRO

An advanced evolution of the Spirit platform, the Spirit LS PRO offers precision and flexibility with CO₂ and fiber laser options. Ideal for batch production and detailed craftsmanship, it delivers consistent results with unmatched speed, superior quality, and a user-friendly experience.

Laser Engraver | Mercury III

The Mercury III builds on the series’ dependable performance and improves engraving quality. Servo motor control keeps accuracy at speed; the large bed and simple interface fit mixed sizes and materials. New hardware buttons, a user-friendly panel, and SmartCENTER auto-centering streamline setup and throughput.

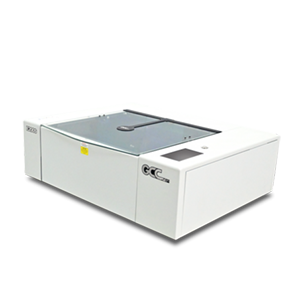

Laser Engraver | E200S Series

The E200S Series provides an easy operating workflow and is able to complete different processing procedures quickly. Most importantly, the E200S Series contains various advanced functions like a blue laser module as an option, with stable quality, and excellent safety features.

Laser Equipment: Frequently Asked Questions

Q: What are the pros and cons of laser equipment?

Laser equipment offers high precision, non-contact processing, and excellent results on complex shapes, which greatly improves efficiency and product quality. On the other hand, it requires a higher upfront investment and proper fume extraction or filtration when working with certain materials.

Q: What’s the difference between laser cutting and laser engraving?

Laser cutting slices completely through materials like acrylic or metal with clean edges and high accuracy, while laser engraving removes only the surface layer to create patterns, text, or codes on items such as gifts, signage, and electronic parts. GCC LaserPro systems deliver both with speed and precision.

Q: Is laser equipment safe to operate?

Yes—when used correctly. GCC LaserPro models comply with international safety standards and are equipped with multiple protective features, including emergency stop, door sensors, air assist, and fume extraction systems. Some models also support optional enclosures for enhanced protection. Operators should always wear appropriate laser safety eyewear and follow Class 1 (CDRH Class 2) safety guidelines.

Q: What materials can laser equipment process?

Laser equipment can work with a wide range of materials, including wood, acrylic, plastics, stone, leather, rubber, glass, and metals. Fiber laser systems are especially effective for directly marking and engraving metals. For the best results, always match the material with the appropriate laser type and power level.

Q: How long does the laser source last?

With regular cleaning and maintenance, sealed CO₂ and fiber sources can operate reliably for years with stable output.

Q: Do I need special software?

Yes. Laser equipment uses dedicated software and drivers to convert designs into toolpaths. GCC LaserPro models integrate with common design tools to fit seamlessly into existing workflows.

Q: Can beginners use laser equipment?

Absolutely. Entry-level models like E200S Series and C180II are approachable with training and safety gear—great for studios, schools, and customized small-batch work.

Q: How much does laser equipment cost?

Various DIY kits on the market cost only around $100–$300, but they’re limited to light tasks such as surface engraving on paper or wood. By comparison, GCC LaserPro offers professional laser machines ranging from entry-level models to industrial-grade systems, with pricing that reflects factors like bed size, speed, durability, and output quality. At the top end, models such as the Piolas 400 Series or Spirit GLS Hybrid PRO offer larger work areas and stable performance—ideal for long-term, production-grade applications.

Whether you’re in metal fabrication, electronics, or creative design, choosing the right laser equipment boosts quality and efficiency. Type, features, and application fit determine how it performs on your line. Still unsure what to pick? Contact us—we’ll help you match the right system to your throughput, budget, and growth plans.